Tuesday, April 2, 2024

|

Listen to this news

|

The appreciation for handicraft is increasingly growing, marking a trend that harmoniously blends traditional craftsmanship with cutting-edge technology. This shift hasn’t gone unnoticed by furniture manufacturers, who are adapting to meet this rising demand. To ensure someone is not left behind, HOMAG presents a range of innovative technologies designed to streamline the creation of sought-after furniture pieces.

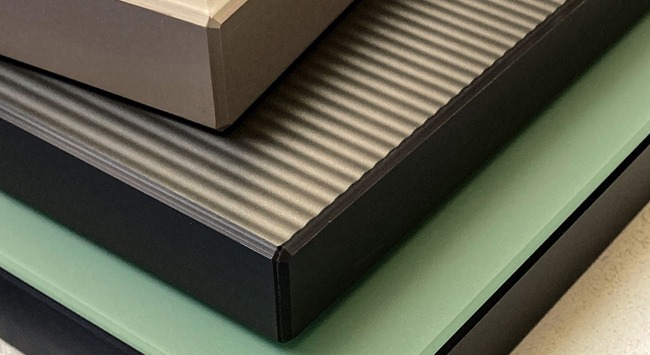

Edgeband with pigmented edge profile

Whether in the kitchen or living area – the demand for textured surfaces made of ceramic, stone and concrete is unbroken. In everyday use, the materials not only have to be visually appealing, but also functional. The pigmented milling radius creates a frameless and seamless look. The transition from panel to edge is practically invisible. The edgeband sets new standards, particularly in combination with laser or airTec technology. This trend can be realised with the EDGETEQ S-500 edgebander, for example.

Fronts with a grooved look

Sideboards, highboards, wardrobes, and sliding doors adorned with grooved textures exude a unique retro elegance, while also bestowing large kitchens with a sophisticated and refined appearance. These grooved surfaces, which can be oriented horizontally or vertically, offer extensive design flexibility when applied as doors, flaps, or drawer fronts, following the natural direction of the veneer. Moreover, employing them on smaller areas serves as a striking high-contrast highlight.

Wood edge- grown on the CNC

Whether dining room, bathroom or living area: customers increasingly want furniture with the individual charm of an original wood edge. HOMAG always concentrates on the high-tec efficiency and that’s why they offer two avant-garde solutions for this:

1) CNC routing from solid wood and the powerEdge Pro Duo unit

2) CENTATEQ E-510 CNC processing center

These can be used to reproduce waney edges simply and as often as required – with panel and edge.

Read more news on: HOMAG

Tags: cutting-edge technology, furniture manufacturers, wood, wood and panel, woodworking industry

Comments: