Friday, December 1, 2023

|

Listen to this news

|

An artificial intelligence application developed by Metsa Group and CollectiveCrunch for detecting insect damage in forests has won the Quality Innovation Award in a competition organised by the Finnish Quality Association, Excellence Finland.

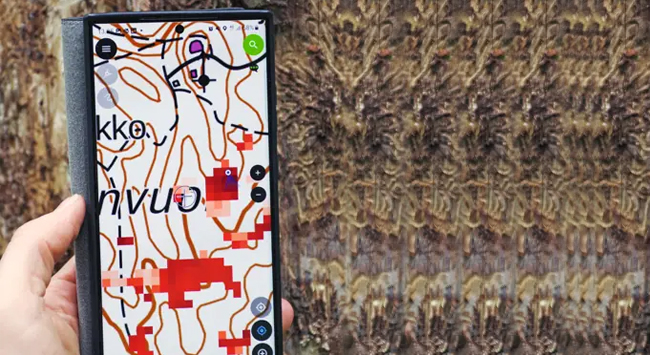

The award-winning application from Metsa Group and CollectiveCrunch detects insect damage in forests such as damage caused by spruce bark beetles before it is visible to the human eye. The application is based on artificial intelligence, machine learning and open data.

The Finnish Quality Association considered the insect damage app the best entry in the innovation category. It is because of the accurate information it provides enables a rapid response to insect damage that helps limit the spread of damage. The application also won the Environmental Innovation category.

Olli Leino, Director, Digitalisation, from Metsa Group’s Wood Supply and Forest Services says, “Global warming has rapidly increased the risks to the health of Finnish forests. In 2022, there was more bark beetle damage, and the affected area spread further north than ever. We decided at the time that we needed a real-time method for detecting insect damage to maintain forest health and carbon sinks in our changing climate. The AI application we developed with CollectiveCrunch will help us and forest owners work together to take care of the health and carbon sinks of our forests.”

The Quality Innovation Award is both a national and international innovation competition that rewards interesting high-quality innovations. The competition criteria include novelty value, usability, learning, customer orientation and effectiveness. Metsa group’s innovative artificial application correctly won the award for its efficiency and high quality. The company is also advancing towards a better future with other collaboration projects. It in collaboration with equipment suppliers, developed a continuous production model for sawmills, where sawmill operations are controlled from a central control room without any manual work stages. The know-how and technical advances achieved in this work will benefit equipment suppliers and the competitiveness of the entire mechanical forest industry in the years to come.

Read more news Metsa

Tags: CollectiveCrunch, Metsa, Metsa Group, Quality Innovation Award, wood, wood and panel, woodworking, woodworking UK

Comments: