Tuesday, November 15, 2022

|

Listen to this news

|

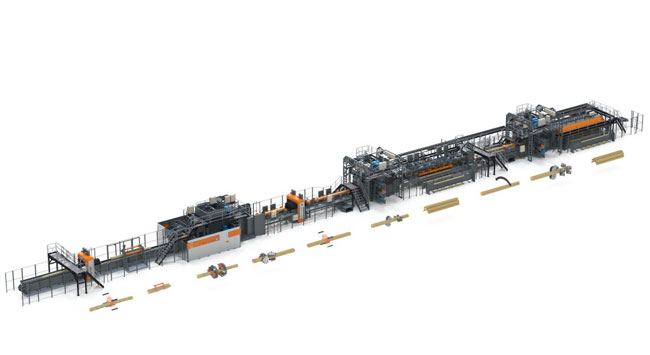

Koskisen recently invested in a rapidly developing sawmill, that is all set to transform how the sawmill’s personnel and internal logistics operate on a day-to-day basis. However, since the next sawing line will give clients options that weren’t previously available, changes are also coming to the sales division. HewSaw’s large log SL250 model, which consists of three machines : a chipper canter, cantsaw and ripsaw, is the foundation upon which the new sawing line is being constructed. There is currently no other configuration quite like it anywhere, and the sawing line is an overall length of 85.6 metres. Prologic’s sorting and optimization scanners, log spacing control, a log rotator, curve sawing, optimum edging, high-speed feed, scan and set technology, and quick setting changes are just a few of the functions the new line will have.

Especially curated for larger logs

Unlike previously, when the steel used in aviation landing gear was employed, the frames of the chipper canter were made of special steel to ensure longevity. The 400,000 m3 production goal for the new sawmill was determined using two shifts per day for a five-day period. Before the line’s maximum capacity is achieved, according to Koskisen’s Sawn Timber Industry Director Tommi Sneck, volumes can still increase. The line’s top speed is 180 metres per minute, although DX sawing might increase that pace to 230 metres per minute. Considering that Koskisen’s line is designed for sawing bigger logs, faster speeds are not the intended outcome—at least not for now. According to Sneck, only logs with a large diameter will be sawn, at least until the end of 2023.

“The sawing line comes with the DX option, which makes it possible to ramp up the line’s speed and use thinner kerf saws. Thinner kerf saws result in either a higher yield or a longer interval between blade changes. In Koskisen’s case, this would mean a production increase of as much as 200,000 cubic metres. More efficiency can also be achieved by adding circular saw blades to both the cantsaw and the ripsaw,” explains Sneck.

Read more news on Koskisen

Tags: Koskisen, log cutting, logistics, sawmill, SL250 model, wood, woodworking, woodworking and manufacturing, woodworking event, woodworking industry, woodworking UK

Comments: