|

Listen to this news

|

Kleiberit has come up with new line dimension for “HotCoating” which opens up new fields of application in surface finishing.

In close cooperation with the machine manufacturer Huser, Kleiberit has introduced a new technological advancement. At Ligna 2019, both partners already hinted at what will be possible in the future in roll-to-roll coating using the HotCoating process. While systems with a roll width of 400 mm were previously considered standard, it is now possible to finish roll material in a width of up to 1,600 mm. And this opens up new application possibilities in the lamination or surface/edge wrapping of large-format components for interior and exterior use.

The worldwide success of the 400 mm systems encouraged the application engineers to expand the technology in such a way that the principle is retained but the coating width is increased by four.

This meant that some technical hurdles and challenges had to be overcome. The handling of the rollers alone was a new challenge. Whereas up to now the rollers had weights of 25 kg to 30 kg, they now had to be integrated with weights of 250 kg to 300 kg in such a way that the operating smoothness, roll guiding and contact level with the roll material fed into the system remained stable and free of distortion.

The change to increase to these dimensions also requires, for example, that the line can be reached with a loading crane.

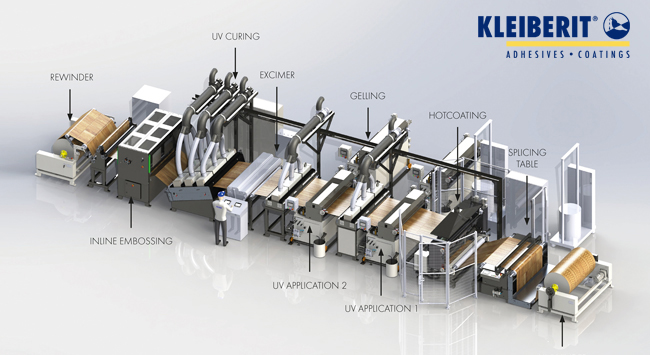

The line basically consists of an unwinder for the material to be coated, the application unit for the PUR HotCoating layer, two or more lacquering units, a pre-gelling station and an excimer area for producing supermatt surfaces, an embossing roller and the winder for the finished roll material.

With line speeds of up to 50 m/min, roll materials made of fleece-laminated veneer, digitally printed paper and thermoplastic films or CPL can be finished and embossed. The flexible properties of the HotCoating coating allow the roll material to be used outdoors, as the PUR layer is resistant to UV light, heat, frost and water. The line is designed in such a way that HotCoating containing corundum can be used, whereby enormous abrasion resistance is achieved, for example for the coating of floors, decking boards or façade elements.

This quantum leap in process technology opens up completely new areas of application in which new products with extreme requirements can be manufactured.

Tags: decor, Kleiberit, Laminated Veneer, roll to roll, Xylexpo

Comments: