Thursday, February 29, 2024

|

Listen to this news

|

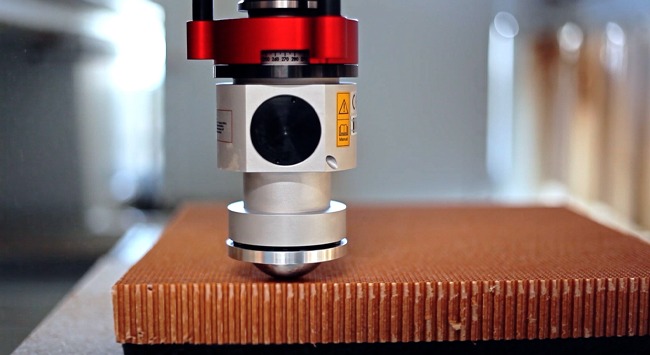

The “SOFT CUTTER PRO FUNCTION LINE” cutting aggregate from ATEMAG is a specialised tool designed to enhance the capabilities of CNC (Computer Numerical Control) machines, particularly for precise cutting of soft materials. This cutting aggregate features advanced technology that enables accurate knife and blade cutting of various soft materials with precision and efficiency.

Extended processing options with the SOFT CUTTER PRO FUNCTION LINE:

CNC machines are indeed indispensable for a wide range of woodworking tasks, including milling, drilling, and sawing. The introduction of the “SOFT CUTTER PRO FUNCTION LINE” cutting aggregate further enhances the capabilities of CNC machines by enabling precise cutting of soft materials such as flexible material panels with thicknesses of up to 150 mm.

This cutting aggregate opens up new possibilities for CNC processing, allowing companies to handle soft materials with the same level of precision and efficiency as harder materials. By incorporating the “SOFT CUTTER PRO FUNCTION LINE,” companies can bring previously outsourced cutting tasks in-house, eliminating the need for external service providers or additional cutting systems. This not only reduces costs but also streamlines the production process.

Moreover, the use of the “SOFT CUTTER PRO FUNCTION LINE” ensures more precise cutting compared to manual execution, leading to higher quality finished products. Additionally, with the ability to process a broader range of materials on a single CNC machine, companies can increase their efficiency and versatility, thereby expanding their capabilities and potentially attracting new clients or projects. Overall, the integration of the “SOFT CUTTER PRO FUNCTION LINE” cutting aggregate represents a significant advancement in CNC technology for woodworking applications.

Technological cornerstones:

The rotary motion on the drive is converted into precise oscillating up and down movements of the tool with an amplitude of 2 mm. The drive with a drive speed of 6000 revolutions per minute results in a cutting frequency of 150 Hz, so that the cuts are carried out with high efficiency and accuracy. The integrated hold-down device fixes the material to be cut in an exact processing position.

With an overall height of approx. 200 mm, the compact cutting aggregate integrates seamlessly into existing CNC machines and can be stored in the tool changer. With the ability to accommodate blade lengths of up to 150 mm (in a Weldon holder for blades with a shaft diameter of 6 mm), it offers a high degree of flexibility for cutting operations involving different material thicknesses.

Modern technology in use:

Before the introduction of the SOFT CUTTER PRO FUNCTION LINE, air-pressure driven systems were the norm. The air supplied to the machine fluctuated in volume and pressure, which led to inconsistent cutting movement frequencies and thus to inferior cutting results. With the current technology, the mechanical drive in the SOFT CUTTER PRO FUNCTION LINE ensures a constantly stable frequency and guarantees a consistent and excellent cutting pattern.

The SOFT CUTTER PRO FUNCTION LINE impresses in various areas of application:

The CNC cutting aggregate is convincing in various industries. In the packaging industry, it enables the precise cutting of cardboard and foam materials, while in the furniture industry, for example, it is used to cut felt. In the textile industry, the cutting aggregate scores points for the precise cutting of fabrics and woven fabrics, including materials such as felt and leather. In the lightweight construction industry, it proves to be extremely versatile and enables the cutting of honeycomb core materials for doors, exhibition stand construction and caravan construction. Cutting polyester, foam or other sound-absorbing materials optimizes the processing of acoustic elements. In industries such as aviation, boat building and aerospace, the unit sets new standards with the precise cutting of honeycomb cores for particularly demanding applications.

The range of possible applications makes the SOFT CUTTER PRO FUNCTION LINE a reliable tool for companies in various industries. It is a unit that can be used on all types of CNC machines. As the knife of the cutting aggregate is always positioned and moved with the cutting edge, ATEMAG recommends using it on CNC machines with at least 4 axes. In 5-axis machines or robots, the CNC can also carry out angular cutting operations.

Read more news on: ATEMAG

Tags: ATEMAG, CNC, wood and panel, woodworking and manufacturing, woodworking application, woodworking industry

Comments: