Wednesday, December 20, 2023

|

Listen to this news

|

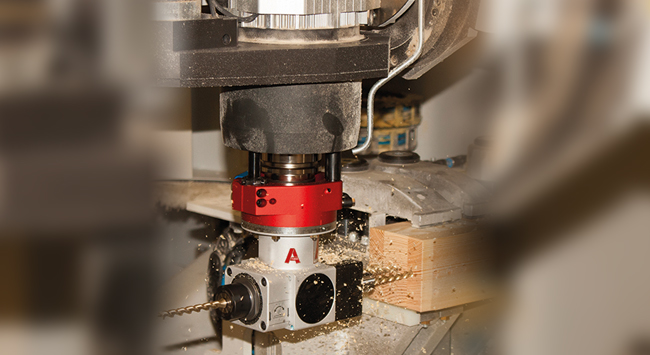

The improved technology of the chisel mortising CNC aggregate from ATEMAG not only provides the user with significant cost savings and time gains, but also increases flexibility in the application areas. ATEMAG is a well-known supplier of CNC aggregate solutions and has been supplying the chisel mortising CNC aggregate with significantly improved technology since June 2023. The commercial technology of a hollow chisel enables the user of a CNC machine to precisely machine square holes, sharp-edged corners and cutouts.

The hollow chisel set consists of a drill and a fixed chisel that works outside the drill tool. In the cooperation of the two tools square holes and sharp-edged corners are made. During the drilling advance, the conically shaped drill is used, while at the same time the chisel precisely shapes the corners around the hole. The resulting wood chips are transported inward to the drill, conveyed upward through the chip space, and ejected.

In previous hollow mortise technology, it was necessary to use custom-built reducing bushings to clamp different tool dimensions. This resulted in costly and time-consuming conversions, especially when a tool with different dimensions was to be used. Based on feedback from the market, ATEMAG has now developed an improvement for this.

Instead of the sleeves that previously centered the tool, a commercially available collet is used. This allows the use of collets available worldwide, which can be obtained directly from the trade. The use of different tools with different geometries is extremely simple, timesaving and therefore more cost-effective thanks to the simple exchange of the collets compared to the individually manufactured sleeves.

The further development of the chisel mortising CNC unit with the innovative collet solution was triggered by the valuable feedback on the handling and reclamping of the unit from the market.

An insight into the CNC Aggregate

An angular aggregate, or angle head, supports the functionality of a CNC machine and acts as an extended arm of the motor spindle.

Motor Spindle

Combining an electric motor, a tool interface, and a tool clamping system, the motor spindle is the heart of the CNC machine. The motor spindle clamps the tools and aggregates and supplies the rotational speed and torque for machining.

C-Axis

The C-axis is a huge gain for the wood industry.

With it, the aggregate can use the clamped-in tools with different approach angles.

Rotations about the Z-axis of the machine are simple and time-saving because the C-axis, equipped with a servomotor, gearing, and a torque support ring, can rotate the aggregate by 360 degrees.

Read more news on: ATEMAG

Tags: ATEMAG, CNC, wood and panel, woodworking industry

Comments: