Tuesday, September 21, 2021

Ammeraal Beltech recently introduces a new range of RAPPLON High Performance Flat Belts for Logistics. With a defined history of offering quality product in the wood industry and known for innovations in the production of conveyor and process belts and meet industry requirements, Ammeraal Beltech participates in LIGNA.Innovation Network to offer solutions for sawmills, furniture manufacturers, finishing lines and board manufacturers.

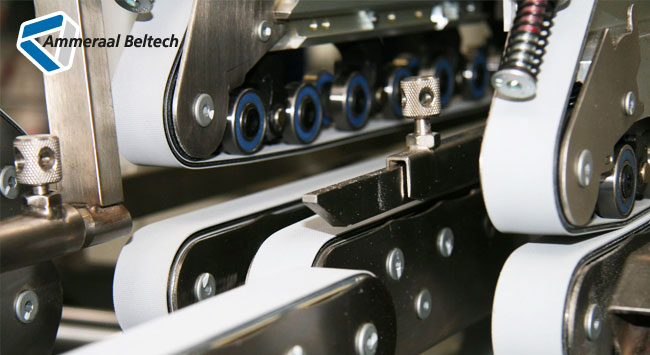

Ammeraal Beltech launches the next-gen RAPPLON High Performance Flat Belts for the Logistics Industry, especially designed to deliver maximum reliability in all processing steps, whether it’s coping with substantial temperature variations, fully loaded stops and starts, incline and decline sections, or any other operational or environmental challenges.

These new black belts square measure fit-and-forget solutions that alter simplified conveyor styles, e.g. our Elastic Belt answer needs no take-up system, giving sturdiness and exactness performance. The serious Duty Roller Drive Belt was developed specifically to be used with serious masses and long transport sections; its Aramid cloth tensile member provides it additional strength to handle these exacting Live Roller applications. The ployurethan cowl material is extraordinarily wear-resistant and therefore the belt’s outstanding flexibility contributes to its overall energy potency. Light roller drive BeltsFor everybody UN agency dislikes time period, the new black lightweight Roller Drive Belts, out there in a very range of normal thicknesses, starting from one.6 mm to 4.5 mm, provide faithfully economical performance over an extended service life. created with cloth tensile members, the belts square measure greaseproof to wetness and show exceptional dimensional stability. The new vary of Elastic Belts square measure designed for slider-bed applications or belt-over-roller conveyors, and may run bi-directionally, creating them ideal to be used with AGV golem load-carriers, sanctioning next-generation supplying robots to load or unload merchandise in advanced fulfilment centres or warehouses. what is a lot of, they are extraordinarily energy-efficient.

Tags: Ammeraal Beltech, ligna, LIGNA.IN, woodworking and manufacturing, woodworking event, woodworking industry

Comments: