Monday, February 26, 2024

|

Listen to this news

|

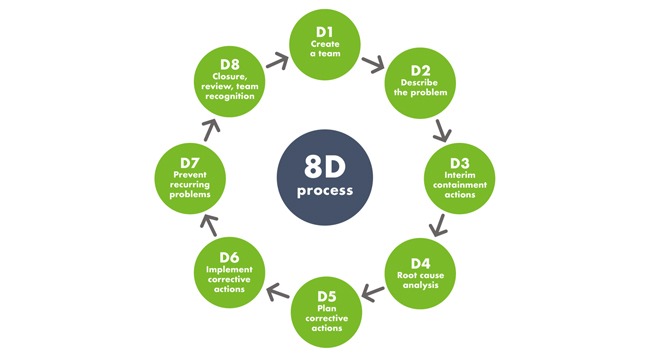

With its commitment to deliver high quality, sustainable and reliable WISA plywood products, UPM Plywood is using the eight disciplines of problem-solving, 8D. It is a systematic tool that helps in quality control while increasing transparency to customers.

eight disciplines of problem-solving is a methodology widely used in automotive industry, and it applies to plywood production as well. The structured framework helps teams to identify, locate and fix the issue at hand.

“At UPM Plywood we use 8D in quality control projects because it is a well-applied method among our customers and it helps us systematically to identify the root cause when there are, for example, deviations in plywood product quality,” says Harri Nieminen, Product Manager at UPM Plywood.

8D not only solves one problem but also helps to eliminate the root cause behind reoccurring problems. Each discipline represents a structured step to take to solve a problem, from creating a team to verifying root causes, preventing reoccurrences, and eventually congratulating the team.

The 8D report increases transparency for the customers

Nieminen describes that the 8D projects are led by product managers and product management, and he says the method works well in plywood quality management.

At UPM Plywood, 8D project is established when there are challenging customer claims.

“We establish 8D projects whenever there are large and demanding claims. Also, if the customer wants us to do an 8D project for some reason related to the product quality, we evaluate the problem and establish the project and the project team from product management, production, and sales. The team varies depending on the project.”

Preventive actions are implemented once the cause has been identified and corrected. The measures can be tracked from the 8D report. The report is also delivered to customer if needed.

“For our customers, 8D method and report proves that if for some reason they have ended up with a faulty product, there will be no similar fault again,” Nieminen sums.

Characteristics of wood are unique

Harri Nieminen remarks that when working in the mechanical forest industry and when processing wood, there may be slight differences in the products.

“How wood behaves as a material is not always understood. If wood material is exposed to water it may swell, or it shrinks when it dries. It is difficult to get a completely flawless product from wood due to the natural characteristics of the material.”

For example, WISA products used for vehicle flooring may often be the only wooden parts in the vehicle.

“Plywood can’t be analysed the same way as metal parts, but the 8D methodology works fine with plywood as well,” says Pekka Kautonen, Manager, Continuous Improvement at UPM Plywood.

“8D has clear steps and leads to a deeper analysis than the direct handling of the customer claim, in which case finding out the actual problem can be forgotten. As we are being experienced and wise, we may quickly jump straight to a solution, even though we should really find out what caused the error or deviation,” Kautonen adds.

Kautonen and Nieminen both state that the 8D tool can be applied lightly or thoroughly, depending on the extent of the problem to be solved.

Read more news on UPM Plywood

Tags: 8D approach, UPM Plywood, WISA plywood products, wood and panel, woodworking and processing, woodworking industry, woodworking UK

Comments: