Thursday, April 25, 2024

|

Listen to this news

|

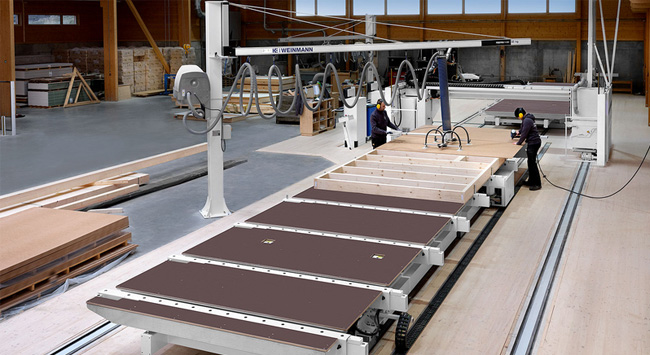

To simplify production sequences and processes in the woodworking industry, HOMAG brings the BUILDTEQ assembly tables that offer a variety of functions and extension options. These efficient assembly tables are here to relieve the burden of employees.

The assembly tables from HOMAG- the BUILDTEQ series are idea for woodworking professionals. It is perfect for the ergonomic and efficient manufacture of rectangular wood frame construction elements and can be extended on a modular basis. The large number of variations allows the assembly tables to be ideally equipped to suit any size of business and then to grow as the business grows. The higher level of prefabrication and the consistently high quality increase efficiency in production operations.

Safety and ergonomics

In contrast to working on the floor, assembly tables offer an ergonomic working height, which contributes to the long-term health of your employees and makes working more comfortable. This not only accommodates your existing workforce, but also makes your business more attractive for new employees. All the table control elements are installed directly on the table, which reduces walking time to a minimum. The assembly tables are fully covered in solid, non-slip sheathing, so they can be accessed with no risk of slipping or falling.

Universal application

HOMAG has designed the BUILDTEQ assembly tables for not just producing wall elements. They can be used universally, including for the production of roof, ceiling and gable elements. The installed bolts are on separate clamping circuits, meaning that one assembly table is not limited to producing a single wood frame element; two elements can be clamped and produced simultaneously.

Potential for modular extension

The modular design of our assembly tables creates potential to continuously increase capacity, even from the entry-level model. In this way, production processes can be optimized incrementally and extensions such as a butterfly turning table or a multifunction bridge can be retrofitted.

Ideal entry-level option for woodworking shops

An assembly table represents an optimal entry-level automated prefabrication solution for small and medium-sized woodworking shops. The assembly tables also make it easier to produce special elements such as gables, bays and knee walls.

Sustainable thinking

Not only is the modular expansion of our assembly tables sustainable with regard to the further development of your business, but the profiles integrated in the assembly tables can be reused in the next expansion stage.

Read more news on HOMAG

Tags: assembly tables, BUILDTEQ assembly tables, homag, wood and panel, woodworking, woodworking and manufacturing, woodworking and processing, woodworking industry, woodworking UK

Comments: