Tuesday, February 6, 2024

|

Listen to this news

|

GREDA – one of the best producers technology and innovation has added two more variations to it’s VENUS series. VENUS V4 and VENUS V5 – these two outstanding innovations of GREDA proved to be the perfect. VENUS is an NC-machining center for the mass production industry engineered to process turning including sanding, shaping and boring operations of solid wood elements.

Detail of the products

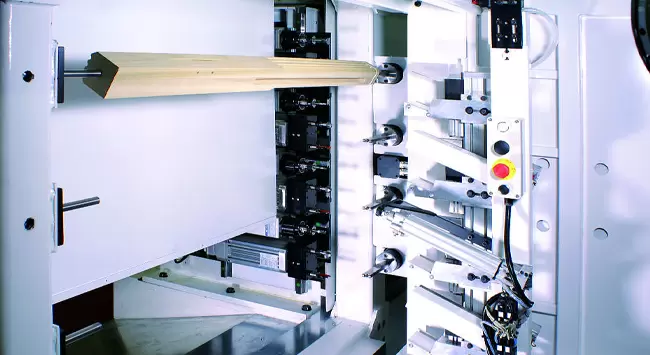

VENUS is an NC-machining center for the mass production industry engineered to process turning, sanding, shaping and boring operations of solid wood elements. VENUS is equipped with multi operating units and a mobile carriage for the rotation and the clamping of the work pieces through a head and tail stock system, in order to execute the machining of 4 pieces in one working cycle.

The working times are very fast thanks to the equipment of multi operating units without tool-changers, and a fully NC-controlled piece pre-loading system.

Fields of Application

VENUS V5

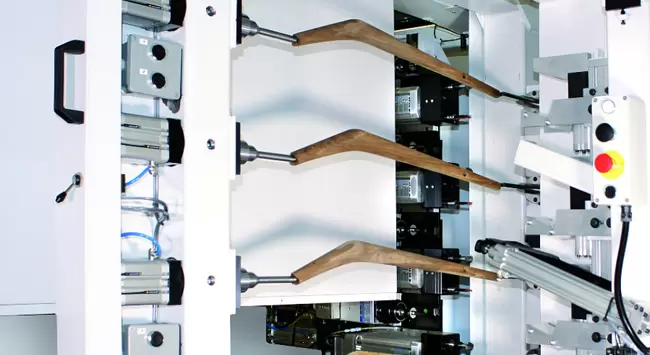

VENUS V5 is a 9-axis numerical control machining center with a milling group to create geometric or flat surfaces, a turning group with cup cutters, a sanding group, and a multifunction group equipped with orientable electro-spindles. VENUS V5, also facilitated by the semi-automatic loading and unloading system, can process up to 4 pieces simultaneously.

VENUS V5 is a 9-axis NC-machining center equipped with a milling group to process geometric or flat surfaces, a turning group with outdrives, a shaping unit and a multi-functional unit with electro-spindles that can be guided to reach every position.

Assisted by a semi-automatic loading and downloading system, VENUS V5 can work up to 4 pieces at the same time.

VENUS V4

VENUS V4 is a machining center equipped with a turning group, with four stations and the possibility of synchronous or asynchronous rotation, and a group of cup cutters made up of four units, which allow copy production. It is the perfect solution for high productivity of turned elements. Thanks to the integrated CAD-CAM system, it allows particular simplicity of programming and great flexibility in production management.

VENUS V4 is a NC-machining center equipped with a 4-position lathe unit that allows synchronous and asynchronous rotation and a 4-unit outdrives milling group for multiple productions. It’s the perfect solution for turned elements high productivity.

Thanks to the integrated CAD-CAM system, it allows easy programming and flexible management of the production.

Read more news on: GREDA

Tags: Greda, Venus series, VENUS V4, VENUS V5, wood and panel, woodworking, woodworking industry, woodworking UK

Comments: