Tuesday, February 20, 2024

|

Listen to this news

|

Unevenness is no longer a problem! All thanks to ATEMAG for innovating extraordinary CNC floating aggregates. ATEMAG – one of the leading enterprises for the engineering, production of aggregates and accessories for CNC machines is ready to help the customers in overcoming the consequence related to the aggregates.

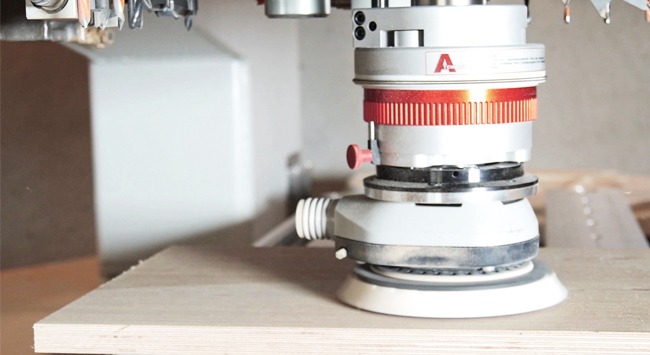

ATEMAG is also renowned as the aggregate specialist from Hofstetten in Baden-Württemberg, Germany, offers an extensive portfolio of floating CNC aggregates that can be used for various machining processes such as drilling, milling, grinding, polishing and sawing. Two of these proven touch aggregates are the SOFT TOUCH PRO FUNCTION LINE and the SOFT TOUCH ONE FUNCTION LINE.

How floating aggregates are useful in CNC sector?

Floating aggregates are indispensable tool holders in CNC machines for machining various materials with unevenness and thickness variations. The tracers of these aggregate types precisely detect the height differences and irregularities of the workpiece during machining and automatically compensate for them by means of an integrated spring mechanism.

This enables extremely precise machining, with uniform holes and milling that maintain exact machining dimensions and depths, as well as ensuring optimum edge finishing over the entire surface of the workpiece.

Now, coming back to the SOFT TOUCH PRO FUNCTION LINE – it offers a great flexibility of different application possibilities. This is the result of the interchangeability of the sensing bell and the tool adapter, which allows different tools with different lengths to be used without the need for repeated tool calibration. Two different height sensing bells are available in the standard equipment of the sensing unit, which can accommodate different tool lengths. In addition, up to 82 different probing devices are optionally available, allowing different applications depending on the material, probing surface, tool width and height. Furthermore, specific customer requirements can be solved individually.

The adjustment range of the SOFT TOUCH PRO FUNCTION LINE is flexibly adjustable in a height of up to 10 mm. Particularly notable is the simple and quick change of the probing bell, which is made possible by the practical bayonet lock. In contrast to competitor products, this change takes place together with the tool change via the ET adapter without any problems, which increases the high flexibility of the probed applications on the CNC machine.

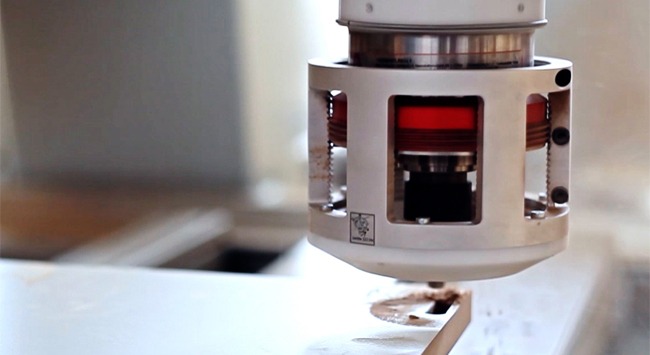

Despite the convincing technology in the SOFT TOUCH PRO FUNCTION LINE, there were good reasons for the ATEMAG technicians to develop another floating aggregate with similar specifications. The result is the SOFT TOUCH ONE FUNCTION LINE, which, in contrast to the PRO, does without the large number of touch probes, but still offers the possibility of processing many standard applications. Due to the permanently integrated ER 32 tool spindle and the always constant touch probe, this floating aggregate can be produced and offered at a lower cost.

Compared to the PRO, the ONE also offers a very large adjustment range of the touch probe (up to 70 mm). The technology also promises high rigidity, which ensures stable tool guidance and tool holding and extremely accurate machining results for the ONE as well. Both CNC units feature fine adjustment for positioning the tracer and, with the use of appropriate quality tools, guarantee optimum machining results.

The planned applications and machining operations ultimately determine which touch unit is the right one for the user. The SOFT TOUCH ONE FUNCTION LINE is particularly advantageous and cost-effective for consistent applications. In contrast, the SOFT TOUCH PRO FUNCTION LINE is more cost effective when the touch probe needs to be replaced more often due to frequent machining. Both aggregates have their strengths and meet different requirements. The right choice of aggregate can save both costs and time.

Read more news on: ATEMAG

Tags: ATEMAG, CNC floating aggregate, Drilling, sawing, wood and panel, woodworking and manufacturing, woodworking industry

Comments: