Monday, November 14, 2022

|

Listen to this news

|

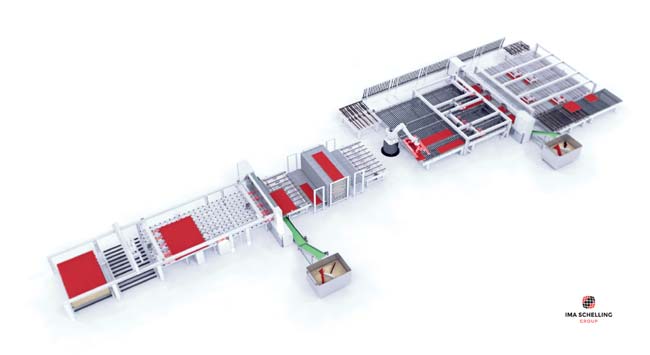

IMA Schelling advances cutting capacity of the wood processing industry by introducing an excellent solution to timber processing through which the cutting capacity of the firm goes up to 6000 components per shift in batch size 1: the high-performance cutting hl 1. Optimally suited cutting concepts make a decisive contribution to the economic success of a furniture production plant. With its high-performance, material- and resource-saving panel saws and dividing systems, the IMA Schelling Group offers the ideal solution for every production strategy and performance class – from standard to high-performance cutting.

IMA Schelling has developed the hl 1 machine concept for an output of up to 6000 components per shift. A longitudinal saw for the production of strips from the raw board is combined with a cross saw, which produces individual components from the strips. “This is not new in itself, but there are a few additional factors that add up to a significant increase in performance,” explains David Schelling, Product Manager Cut-to-size at IMA Schelling.

Higher speed, proven technology

Since a chipping unit is placed in front of the longitudinal saw, one cutting cycle per strip is saved. This has the advantage that the cross saw is relieved. In contrast to solutions previously available on the market, the hl 1 does not multiply the processing units, but the feeding components. In this way, strips are fed to the cross saw independently of one another in up to four tracks and divided up together. In this way, four components can be produced every twelve seconds with just one unit. This not only reduces energy and tool costs, but also makes maintenance much easier.

Flexible modular solution

“As a modular solution, the hl 1 cut offers our customers great flexibility,” emphasizes Schelling. Depending on the production strategy and the available floor space, the modular system can be used to respond to any of our customers’ requirements. The area after the longitudinal saw can be provided with a buffer section or with a strip buffer. It also makes no difference whether the transfer of the strips to the cross saw is to be implemented with a transfer portal or with an industrial robot.

Tags: cutting tools, IMA SCHELLING, technology, wood, wood and panel, woodworking and manufacturing, woodworking and processing, woodworking event, woodworking industry, woodworking UK

Comments: